Precision in Production: The Critical Role of Moldflow in Manufacturing

In terms of industrial production, accuracy and efficiency dictate the pace of innovation and production. Advances in simulation technology, particularly through Moldflow And Casting Analysis and Mold Flow Analysis, have transformed the way manufacturers approach the design and creation of molds for plastic parts and metal castings. These technologies not only improve product quality but also significantly reduce the time and cost associated with development cycles.

The

Impact of Mold Flow Analysis

Mold

Flow Analysis is a necessary instrument for engineers and designers focused on

optimizing the injection molding process. This sophisticated simulation

software predicts how plastic flows within a mold, identifying potential issues

like air traps, weld lines, and sink marks before a single piece is physically

produced. By anticipating these problems, Mold Flow Analysis

allows for adjustments in design or process parameters early in the development

stages, thereby enhancing the structural integrity and aesthetic quality of

final products.

Streamlining Design and Production

The

ability to simulate and tweak designs digitally is a game-changer in

manufacturing. It significantly shortens the product development timeline by

minimizing the need for multiple physical prototypes. This not only saves

material and labor costs but also speeds up the time to market for new

products. Additionally, Mold Flow Analysis assists in selecting the most

suitable materials and the most efficient design specifications, ensuring

optimal performance and cost-effectiveness.

Enhancing

Sustainability in Manufacturing

Using

Mold Flow Analysis also contributes to environmental sustainability. By

optimizing the mold design and minimizing the material used, manufacturers can

reduce waste and improve the energy efficiency of their production processes.

This dedication to environmentally friendly methods is growingly crucial. in a

world where consumers and regulatory bodies demand more environmentally

friendly products and processes.

Expanding

Capabilities with Moldflow And Casting Analysis

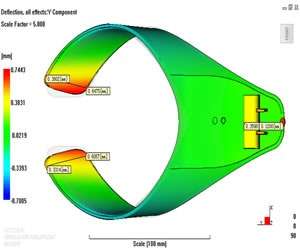

While

mold flow analysis focuses on plastic injection molding, mold flow and casting

analysis extend these capabilities to metal casting. This analysis includes

simulations of mold filling, solidification, and cooling, as well as the

prediction of defects that could occur during the casting process, such as

porosity or thermal stresses. The insights gained from Moldflow And Casting Analysis

enable foundries and manufacturers to refine their casting methods, enhance

mold designs, and ultimately produce stronger, higher-quality metal components.

Conclusion

In

conclusion, the integration of Moldflow Casting Analysis and Mold Flow Analysis

into the manufacturing technique marks a major development in the manufacturing

of both plastic and metal components. These technologies empower manufacturers

to achieve greater precision, efficiency, and sustainability. For more

information and expert guidance on incorporating these advanced simulation

tools into your manufacturing operations, visit FEAmax.com. Embracing these

modern techniques is crucial for any company aiming to lead in today’s

competitive manufacturing industry, ensuring that each product not only meets

but exceeds the rigorous standards of quality and performance.

.jpg)

Comments

Post a Comment